The reliable partner at your side for 120 years

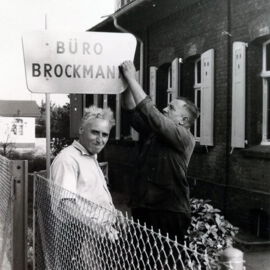

1901 – 1950

Businessman Alfred Brockmann establishes the company in Cologne. Initially, only the handling of drop shipments takes place. After the Second World War, Alfred Brockmann transfers the company to his nephew, Mr. Roeckerath. Together with his university friend, Dr. Ernst Meulemann, the foundation stone is laid for the company's new beginnings.

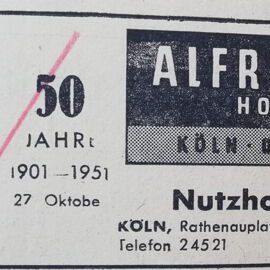

1951 – 1967

After the war, great successes are achieved very quickly and Dr Meulemann founds a subsidiary in Düsseldorf, into which the entire company is later absorbed. The first sawn timber imports from Russia are launched and the foundation stone for the plywood business is laid with imports from Finland.

1978 – 1979

Dr Ernst Meulemann takes his son-in-law Dr Hans-Gerd Glatzel into the company as a partner. The name is changed to Brockmann-Holz GmbH.

1980 - 2000

Dr Hans-Gerd Glatzel becomes the new managing director. In the years that follow, the focus is placed on importing plywood from Europe and Brazil. In addition to supplying formwork to the construction sector, large trading companies are also supplied. 1994 sees the foundation and development of Brockmann-Holz Recycling GmbH & Co. KG for the sustainable recycling of wood waste.

2000 – 2010

Development of the Asian plywood business with imports from China. Sales of sawn timber to the packaging industry also pick up speed. The treatment of wood waste is relocated to a new site in Krefeld in 2006 and further expanded there.

2011 – 2014

Like his father-in-law before him, Dr Glatzel enlists the support of his son Gerd-Friedrich Glatzel. Two years later, he is appointed sole managing director and successfully manages the company since in the 4th generation.

2015 – until today

At the end of 2015, the company headquarters relocate from Düsseldorf to Krefeld-Linn in order to drive forward the 120-year success story at a new location. In addition to Brockmann-Holz Recycling already established there, two large warehouses equipped with new storage technology, a modern office building, a wood processing plant and a drying chamber are built on the more than 30,000 sqm site.